Injection Moulding Machine

Chen Hsong MK6.6 Series

(JM88 up to JM658 tons)

Major Advantages of JM-MK6.6 Machines

- Brain of the machine – Superiority Guaranteed

Power and ergonomics perfected. - Advanced toggle design from decades of experience

Optimized motion control profile guarantees high speed with high stability.

- High-strength platens ensure high-quality precision parts

Patented high-strength platens have low deformation. - Perfect parts from a high-precision injection unit

Linear guide rails for injection – highly stable, high precision, high repeatability.

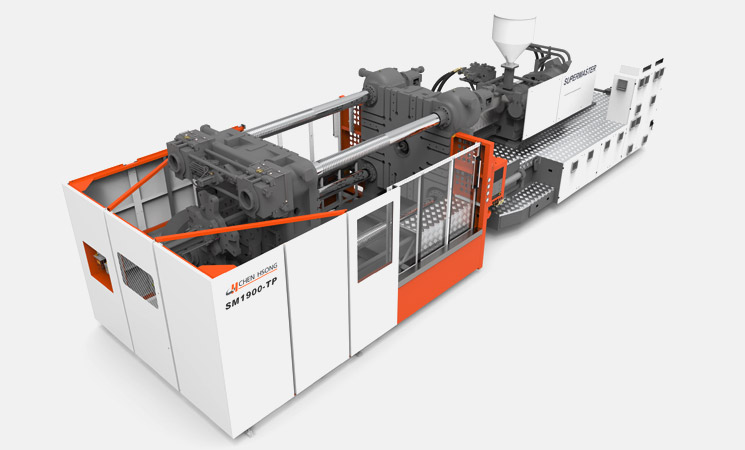

Chen Hsong Supermaster Two Platen Series

(SM700 up to SM6500 tons)

* Under the License Agreement, Mitsubishi has granted Chen Hsong to use Mitsubishi’s technology and know-how necessary for the manufacture and sale of large size two platen type hydraulic injection molding machines.

Major Advantages of SM-TP Machines

- Incredible Speeds

Up to 750mm/s speed in Clamp open/close. - High Efficiency Innovance Servo Motors

Reducing energy consumption up to 80%, bringing high precision and super low noise operation. - Unique Mix and Match Capability

You may select from 14 sizes of different clamping units and match them with 29 different injection units.

- Speedy Setup

Fast die height and clamping setup technology. (Die height adjustment in only 20 seconds). - High Speed Clamping Pressure Build Up

- High Pressure Injection and Fast Speed Recovery

- Optional Ejector on the Fly

Chen Hsong Spark AE Series

(AE100 up to AE360 tons)

Major Advantages of Spark AE Machines

- Intelligent Control

1. Auto Stress Release System (ASRS) Ensures high-yielding parts by dynamically releasing internal stresses.

2. High Speed CPU for Real-time Calculations Software dynamically adjusts and compensates all hardware motion during injection, holding, recovery, ejection and clamping.

3. Ultra-fast Responses High-end CPU enables lightning speed closed-loop calculations for ultra-fast dynamic responses, superior precision and perfect repeatability. - Efficiency and Speed

Faster dry cycle time than competition offerings due to SPARK AE’s highly responsive advanced servosystem. - Stability and Quality

Longer sustainable holding time than competition offerings under real-life production conditions.

- Reliability and Precision

Patented Circular Platen design ensures even stress distribution and low deformations for higher quality parts and superior dimensional stability, comparison between major brands on platen deformation under similar clamping conditions. - Applicability

One machine to make them all – from ultra-thin parts requiring ultra-fast speed and responses, to ultra-thick parts demanding rock-solid stability under low-speed and prolonged high-pressure conditions. - Power Efficiency

Redefining the benchmark for Low Energy Consumption, 20.7% lower power consumption than competition offerings.